We’re proud to introduce a new feature that empowers online monitoring users to solve failures more confidently, even when they’re unfamiliar with a specific machine.

Creating and standardizing inspection procedures ensures that all maintenance activities are executed consistently and efficiently. Now, your team’s operational knowledge is enhanced by Tractian’s AI database and generative capabilities.

In addition to the new tools for procedure creation, be sure to check out the other updates included in this release:

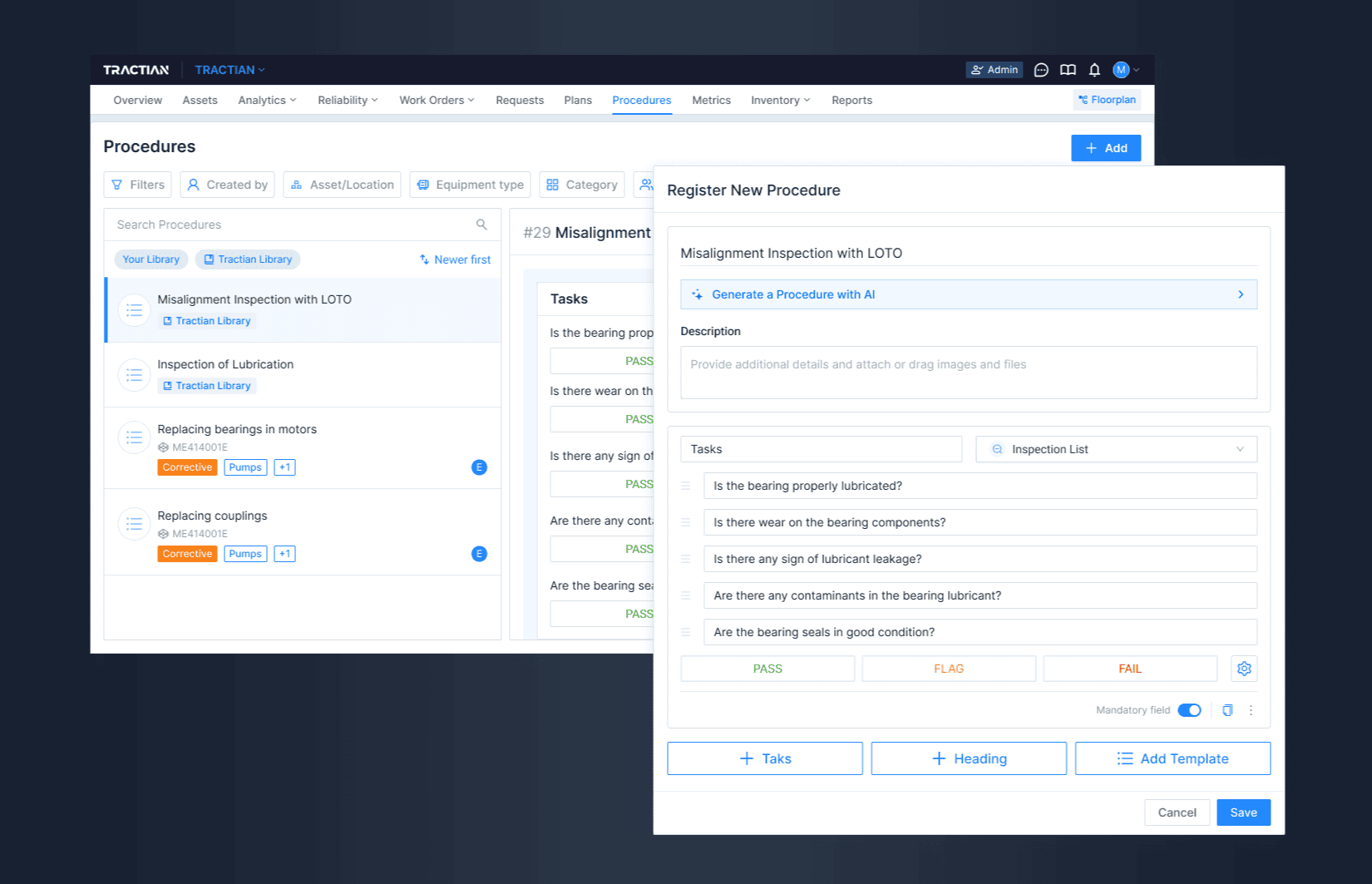

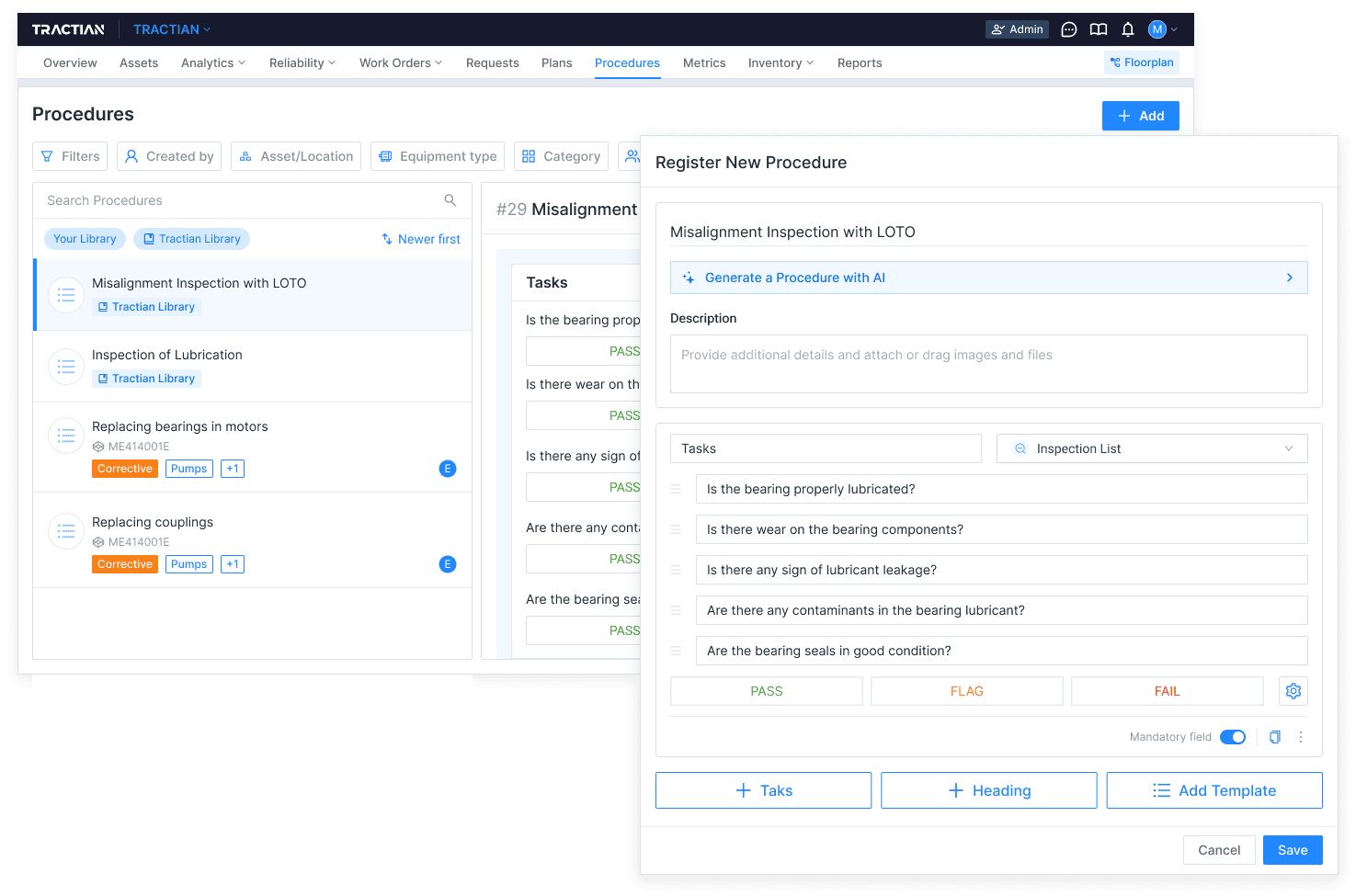

Controlled SOPs for reliable and efficient maintenance execution

You can now create Standard Operating Procedures (SOPs) and assign them to Failure Inspections in the platform. These can include mandatory protocols, checklists, safety measures, and any other key guidelines that ensure process compliance and more robust diagnostics.

Your team can build checklists manually or generate them using our AI, Tractian Copilot.

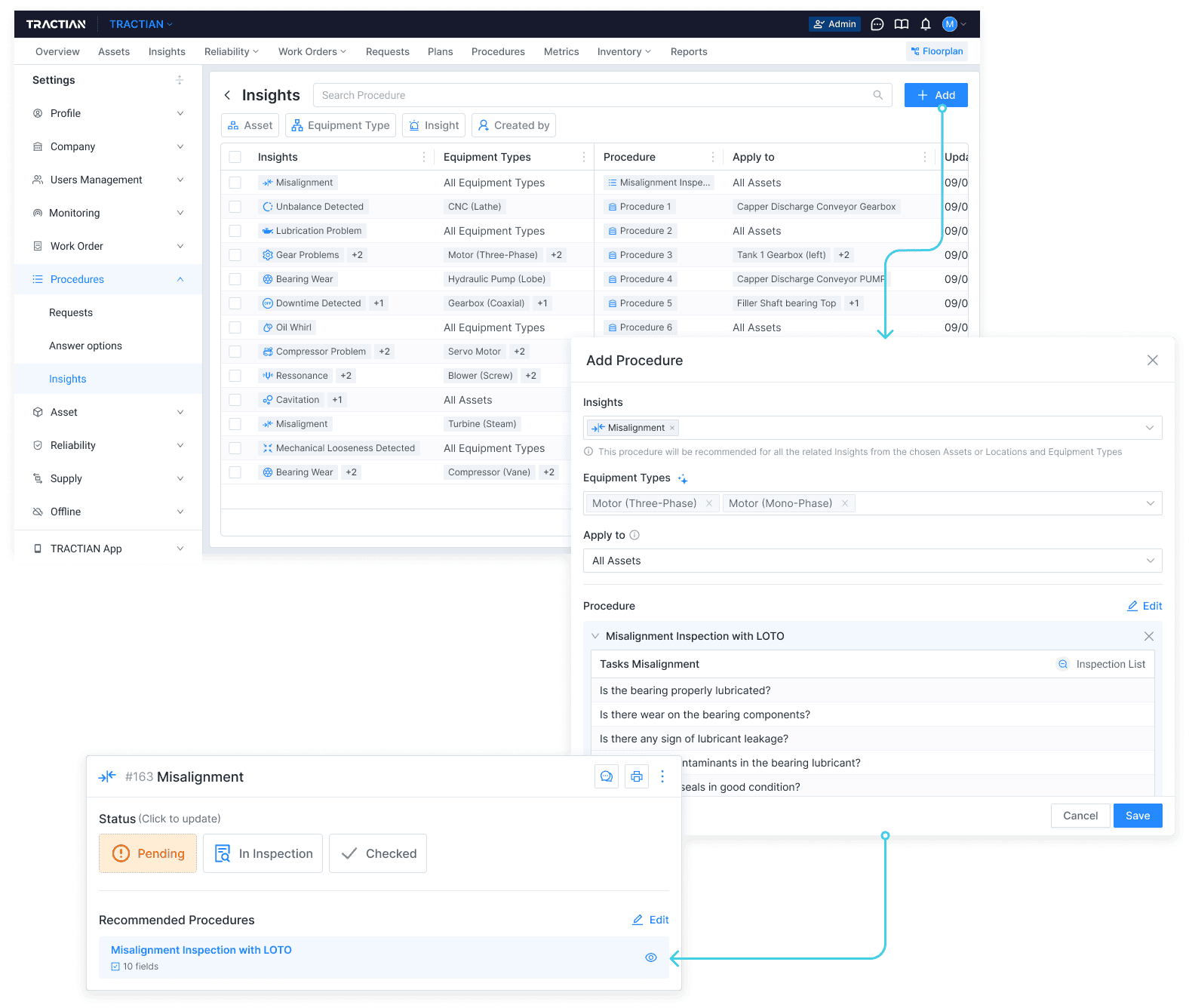

By entering your instructions, Traction Copilot combines your input with the historical data from your own assets, as well as similar ones in the broader system, to generate detailed procedures tailored to your machine. Whether you’re inspecting an ammonia compressor with chronic lubrication issues or a gear motor with seal problems, the SOP is made to fit.

You can also configure where and when procedures are recommended, linking them to specific asset types, insight categories, or a combination of both.

These tools help your team standardize workflows quickly and ensure compliance with your plant’s safety and quality standards, making inspections more accessible for every technician and boosting the reliability of data and indicators.

Why it matters

Reproducibility in maintenance — the ability to perform tasks consistently across technicians — is key to asset reliability.

When everyone follows the same procedures and checklists, operational variability decreases. This increases the predictability of asset behavior and reduces the risk of recurring failures. Without this level of standardization, maintenance becomes inconsistent, making it harder to build a sustainable reliability program over time.

How it works

- Register your custom SOPs on the Procedures page

- Create new checklists using Tractian Copilot

- Link SOPs to specific insights and requests from the Settings panel

- Add mandatory SOPs to Failure Inspections to ensure every step is completed before closing

Visit the Help Center articles to see the full walkthrough.

Results

- Process standardization across maintenance teams

- Reduced variability in inspections and interventions

- Teams empowered to inspect a wide range of machines

- Lower risk during on-site activities

Click here to see the full list of new features.